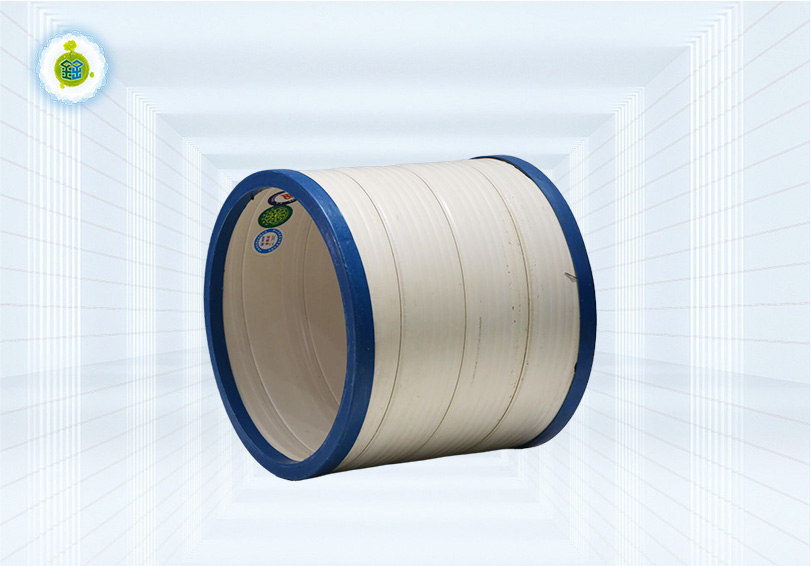

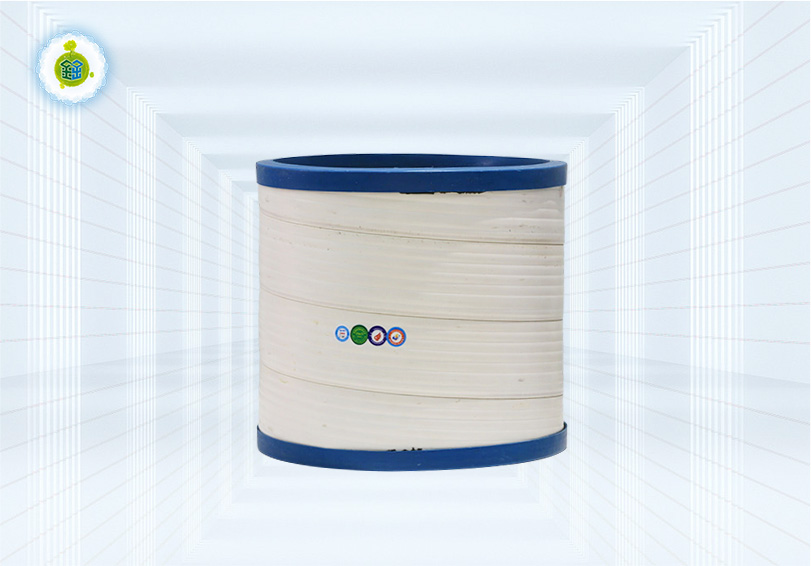

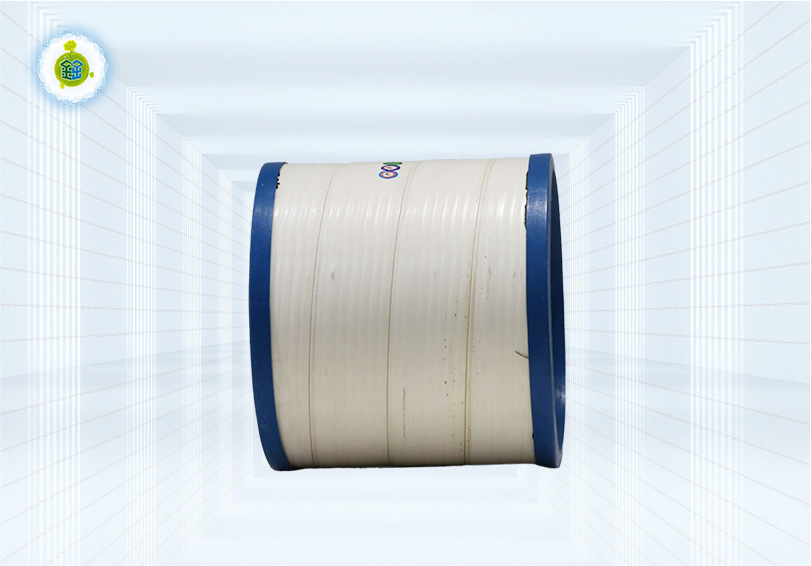

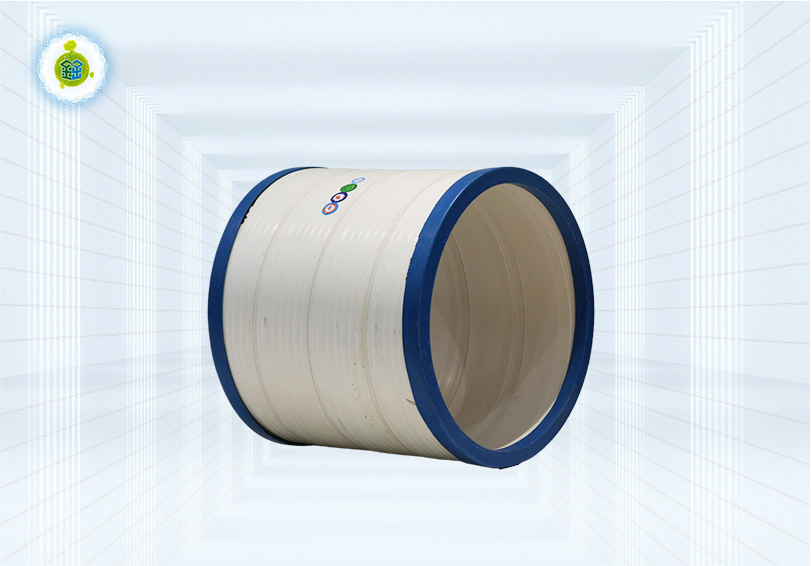

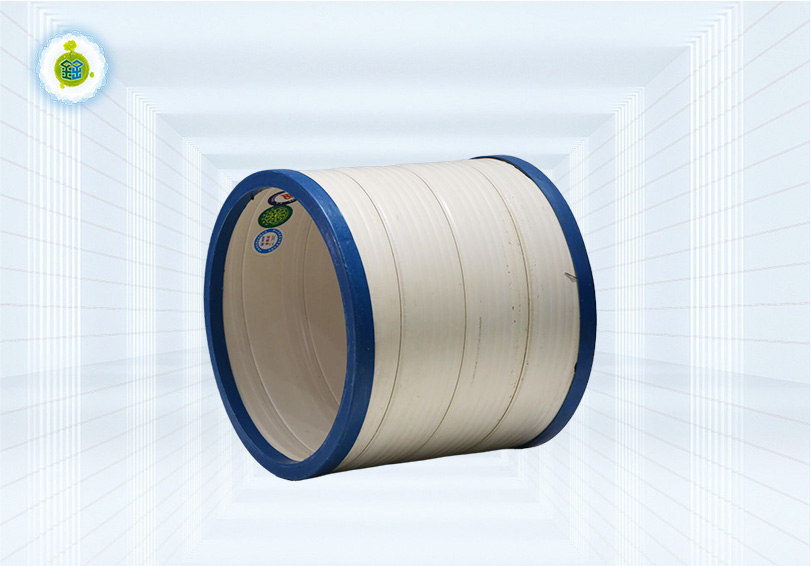

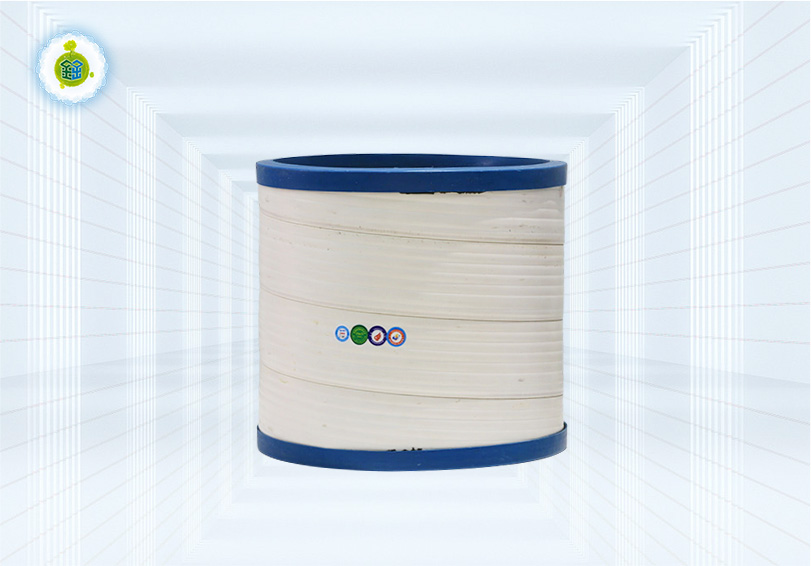

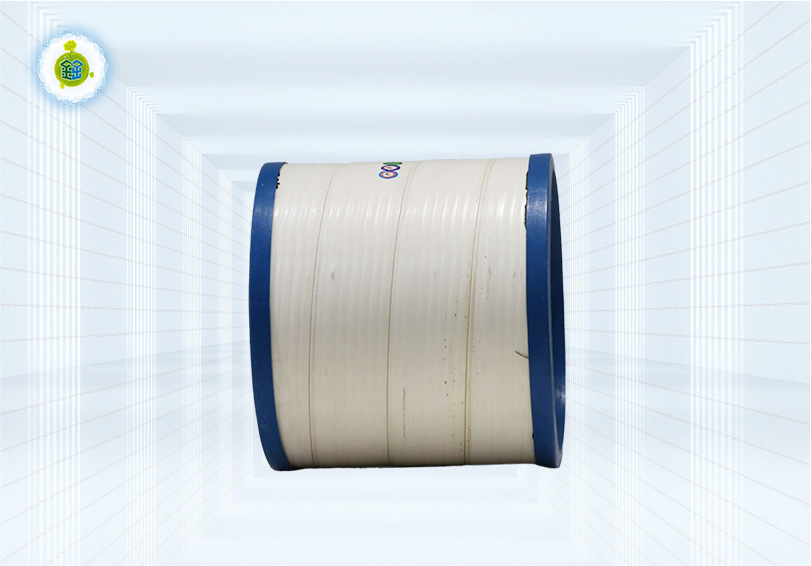

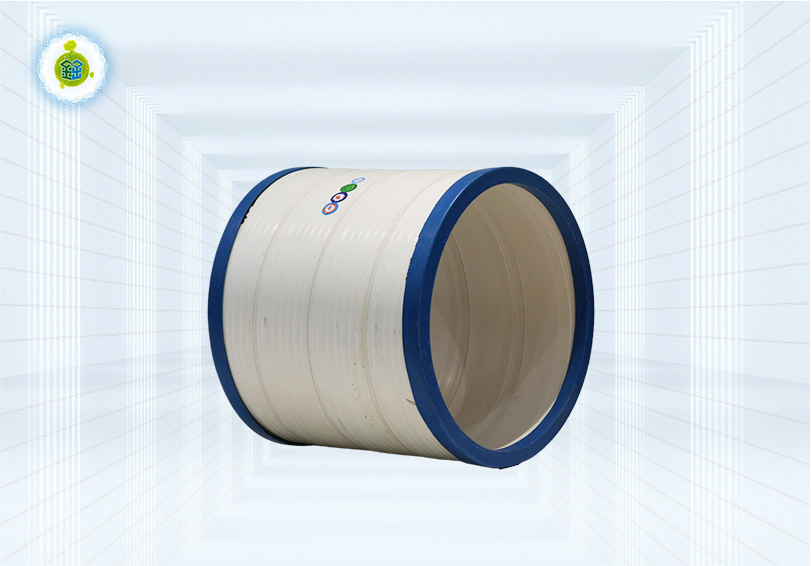

PVC-U Spiral Winding Pipe

PVC-U spiral winding pipe is made of polyvinyl chloride (PVC) resin as the main raw material, adding the necessary additives to form a mixture, plasticized and extruded into a PVC-U sheet with a locking structure on the outside, and then made into single-layer, double-layer and multi-layer spiral winding pipe by winding technology.