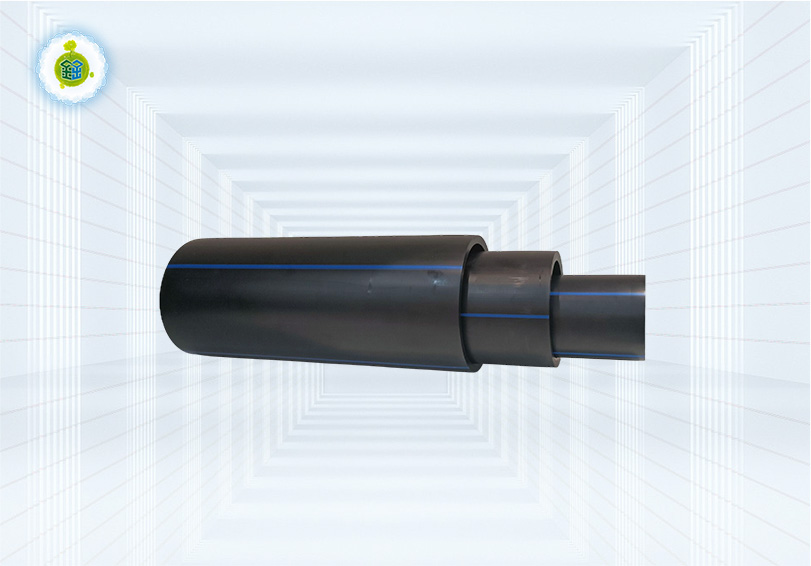

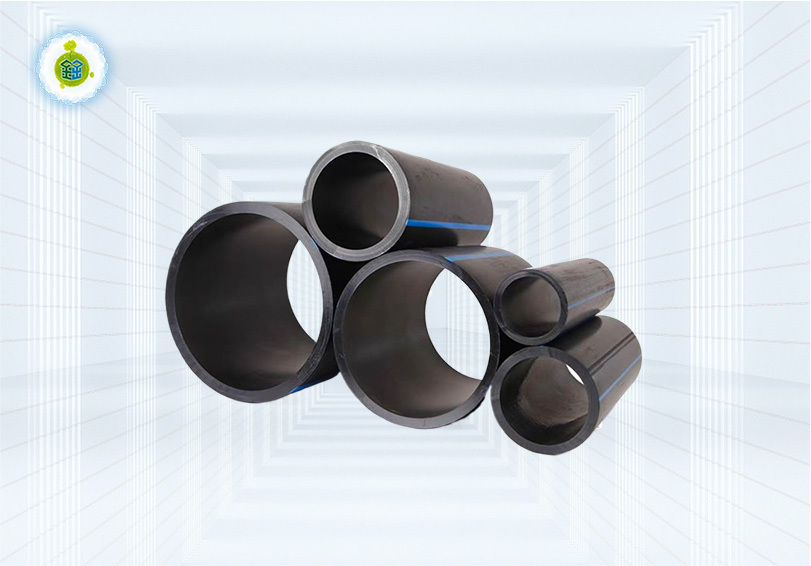

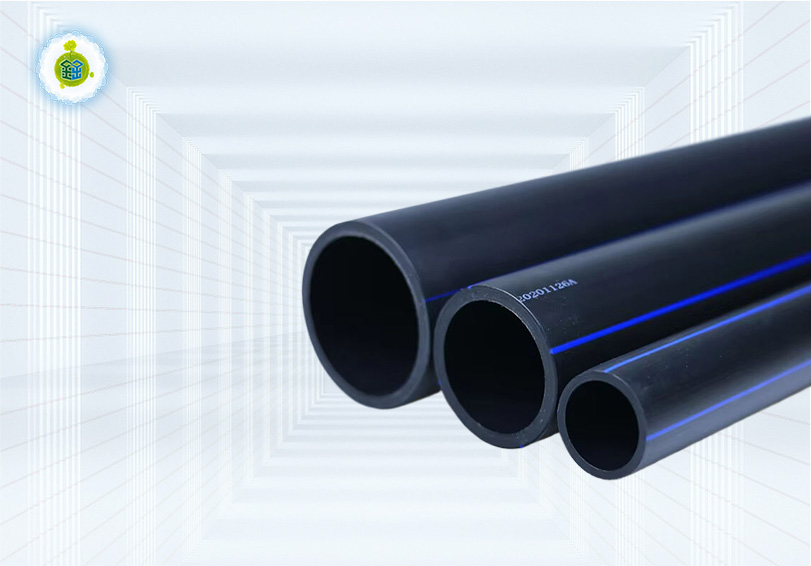

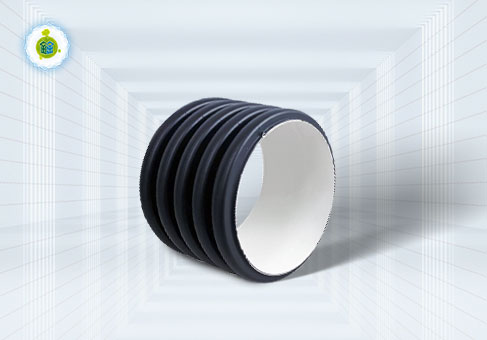

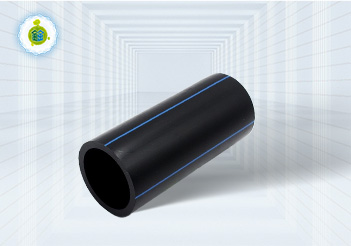

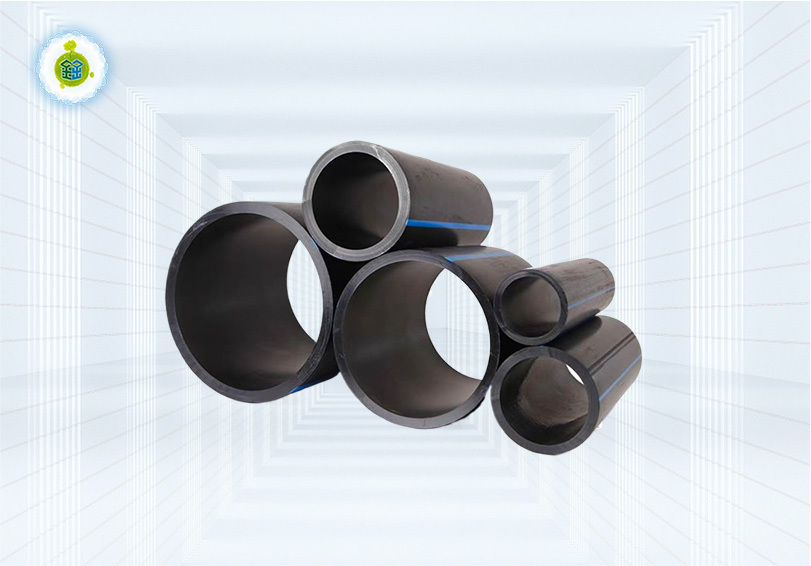

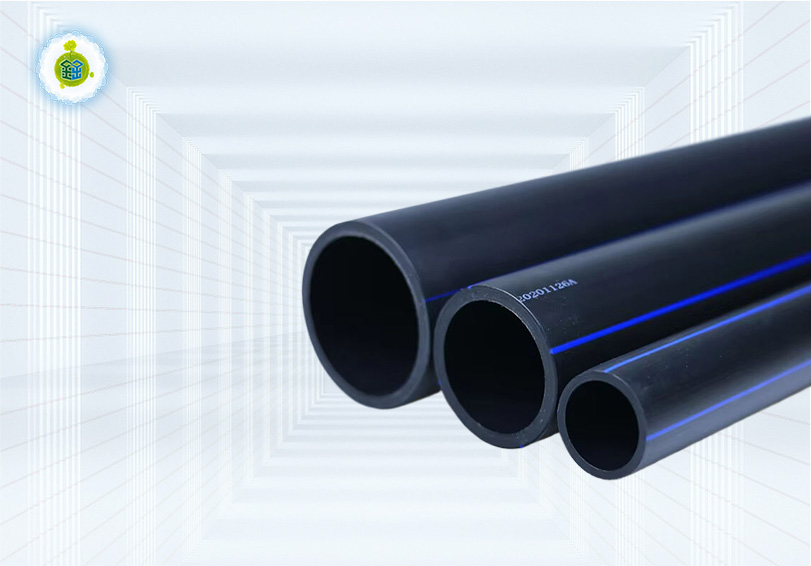

PE Pipe For Water Supply

PE pipe for water supply is made of high quality polyethylene resin as the main raw material, adding the necessary additives such as antioxidant and ultraviolet absorber etc., extruded by the plastic extrusion machine and processed into a new type of plastic pipe.